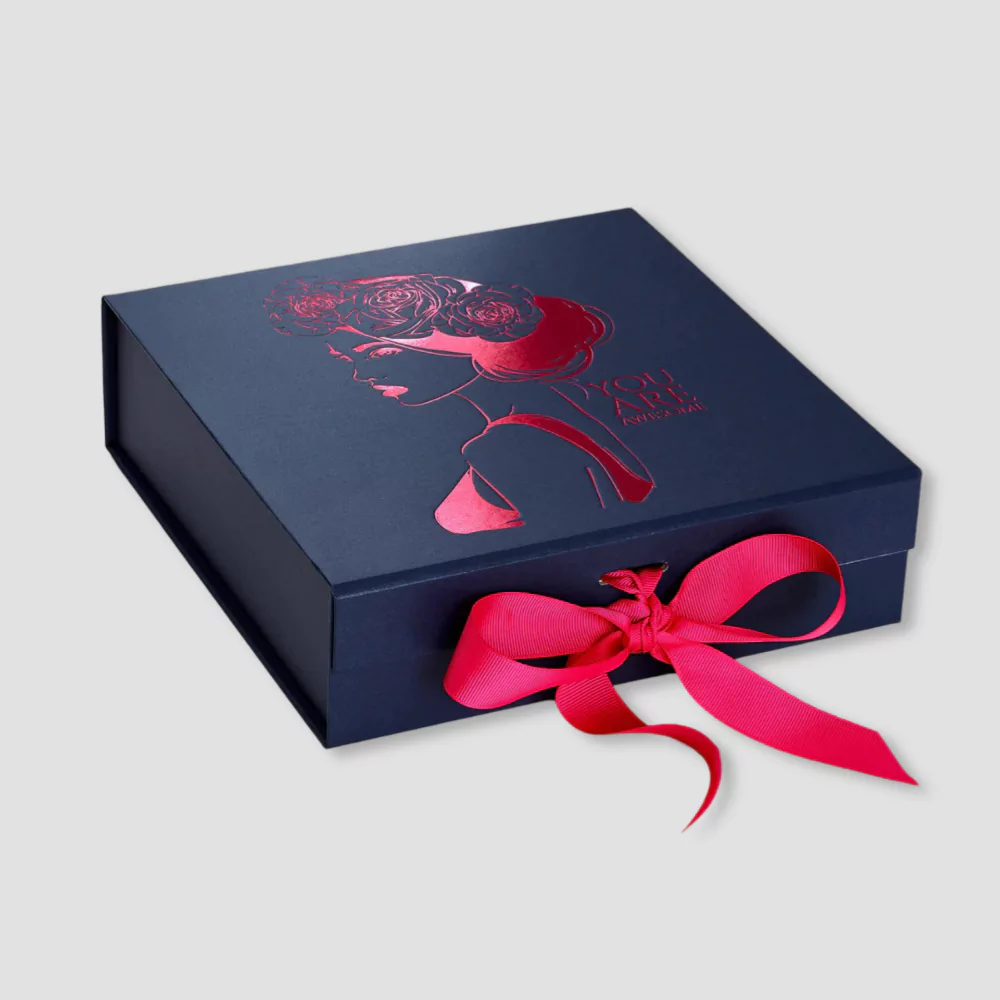

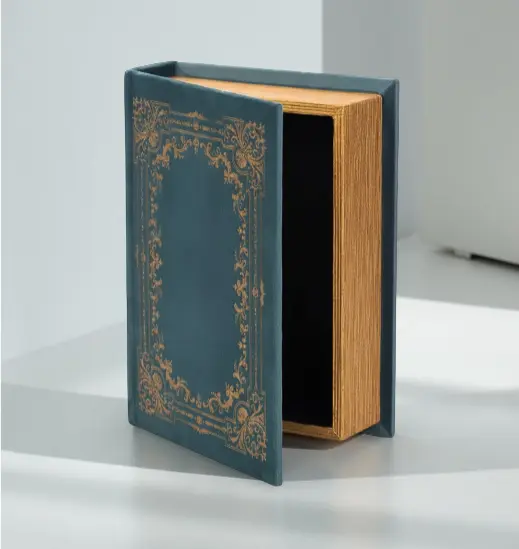

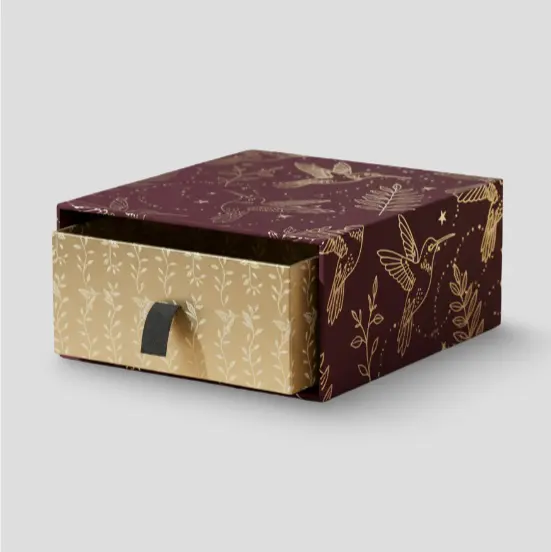

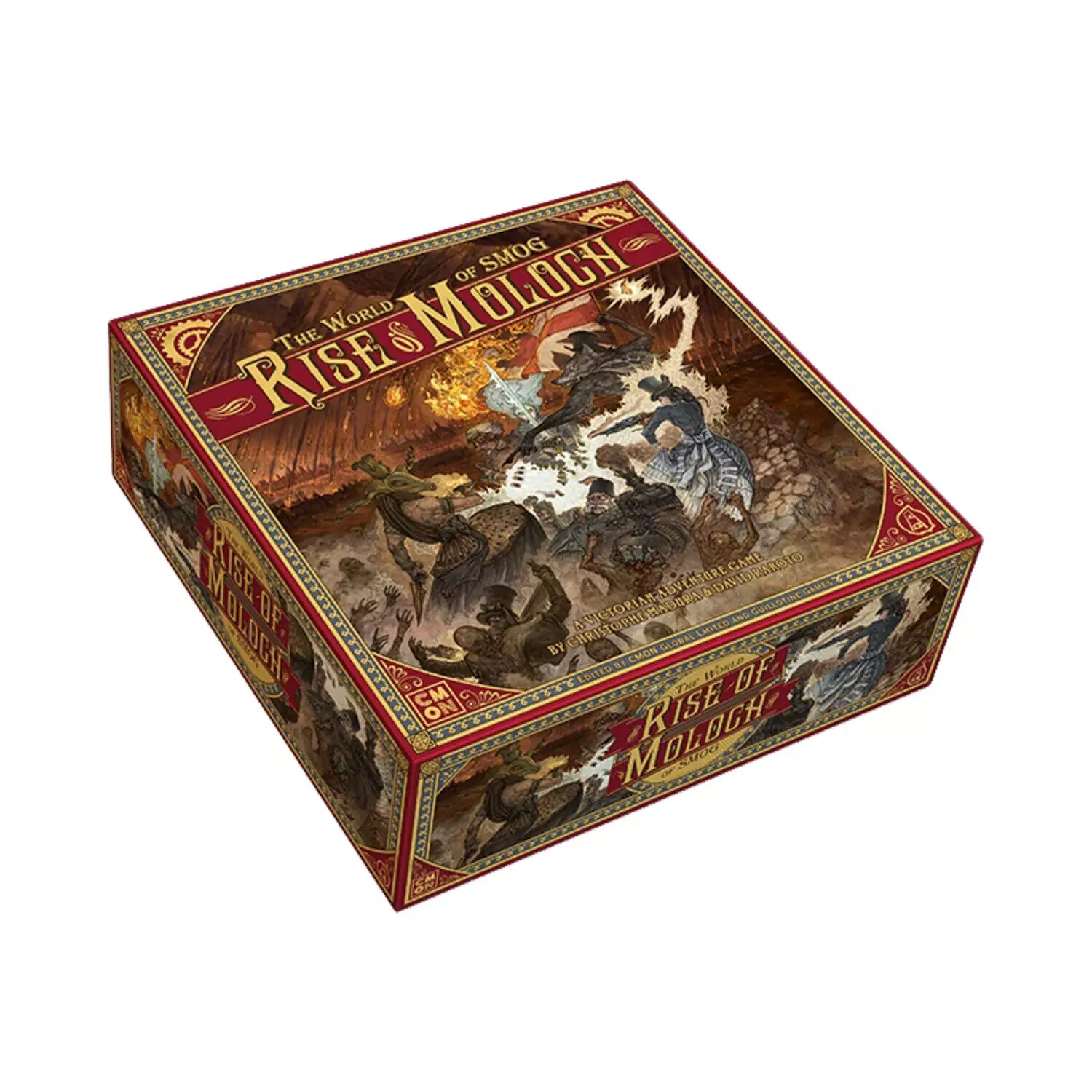

Tray and Sleeve Box

Customised tray and sleeve boxes offer a refined and practical packaging solution designed for brands that value both presentation and product protection. Featuring a sturdy inner tray and a smoothly sliding outer sleeve, these boxes provide an elegant unboxing experience while keeping items secure. They can be tailored with premium materials, advanced printing, and luxury finishes, making them ideal for cosmetics, electronics, confectionery, apparel, CBD items, and high-end gift packaging. Their strong structure and modern look make them a preferred choice for retail and e-commerce brands.

No Die & Plate Charges

Offer valid with a minimum order quantity of 1,000 units.

Quick Turnaround Time

Experience fast, reliable production with our streamlined process—ensuring your custom packaging is delivered on schedule without compromising quality.

Free Shipping

Enjoy hassle-free delivery at no extra cost. We provide free shipping on all qualifying orders, ensuring your custom packaging arrives safely and on time—without additional fees.

Custoimze Size & Style

Get packaging tailored exactly to your product with fully customizable sizes and styles.

Free Designing

Bring your ideas to life with complimentary professional design services. Our expert team helps you create stunning artwork and layout.

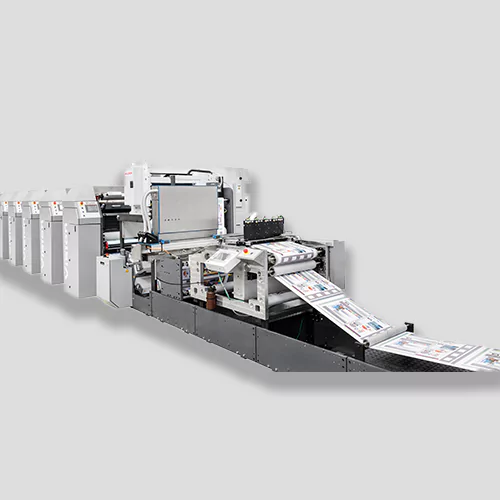

Offset Printing

Offset printing is a widely used commercial printing technique where ink is transferred (or offset) from a metal plate to a rubber blanket, and then to the printing surface—usually paper.

It is ideal for high-volume, high-quality, and cost-efficient printing.

Digital Printing

Digital printing is a modern printing method that transfers digital files—such as PDFs, JPGs, and design layouts—directly onto materials like paper, vinyl, fabric, and plastic.

Unlike offset printing, digital printing does not require plates, which makes it fast, flexible, and ideal for small to medium print runs and personalized printing.

Flexo Printing

Flexo printing (Flexographic printing) is a modern, high-speed printing process used mainly for packaging materials. It uses flexible rubber or photopolymer plates, which transfer ink onto a variety of substrates such as paper, plastic film, foil, cardboard, and labels.

Flexo is ideal for continuous, large-volume printing and is widely used in industries like food packaging, labels, corrugated boxes, and wrappers.

Rotogravure Printing

Rotogravure printing, also called Gravure printing, is a high-speed, high-quality printing process where the image is engraved onto a metal cylinder. The engraved cells hold ink, which is transferred directly onto the substrate.

It is mainly used for long-run, high-volume printing, especially in packaging, magazines, gift wraps, and decorative laminates.

Screen Printing

Screen printing, also known as silk screen printing or serigraphy, is a printing technique where ink is pushed through a mesh screen onto a surface using a squeegee. Certain areas of the screen are blocked (using stencil or emulsion) so that ink passes only through the desired image area.

It is widely used for printing on fabrics, garments, paper, plastics, glass, metal, wood, ceramics, and many other materials.

WHITE CARD

-

Description: Smooth, bright white paperboard.

-

Features: Stiff, printable, good for high-quality graphics.

-

Uses: Business cards, brochures, invitations, packaging for luxury products.

KRAFT CARD

-

Description: Brown, recycled paperboard with natural appearance.

-

Features: Eco-friendly, strong, rustic look.

-

Uses: Eco-packaging, shopping bags, tags, boxes, food packaging.

Texture Card

-

Description: Paper or board with embossed or textured surface (linen, linenweave, hammered).

-

Features: Adds tactile feel and premium appearance.

-

Uses: Invitations, greeting cards, high-end packaging, certificates.

Corrugation

-

Description: Multi-layered paperboard with fluted middle layer.

-

Features: Strong, durable, provides cushioning and protection.

-

Uses: Cartons, shipping boxes, product packaging, industrial packaging.

Special Cards

-

Description: Specialty papers or boards with unique features like metallic finish, holographic effects, pearlescent sheen, or soft-touch coating.

-

Features: Premium look and feel, visually striking.

-

Uses: Luxury business cards, gift packaging, limited edition brochures, promotional materials.

MATTE

-

Soft, elegant, non-reflective finish

-

Premium appearance

GLOSS

-

Shiny and vibrant

-

Makes colors pop

SOFT TOUCH

-

Smooth, velvety texture

-

Used in luxury packaging

ANTI SCRATCH LESS

-

Scratch-resistant surface that prevents scuffs and marks

Foiling

-

Foiling is a finishing process where a metallic or pigmented foil is pressed onto paper using heat and pressure.

Key Points

-

Creates shiny metallic effects (gold, silver, rose gold, holographic).

-

Adds a luxury, premium look.

-

Used in packaging, invitations, logos, business cards, and book covers.

-

Embossing

-

Embossing creates a raised (3D) effect on the surface of paper or board.

Key Points

-

Made using male and female dies pressed together.

-

Enhances logos, titles, patterns, and design elements.

-

Gives a premium and tactile feel.

-

D embossing

-

Debossing is the opposite of embossing. It creates a pressed-in (recessed) design on the surface.

Key Points

-

Imprint goes downward into the material.

-

Ideal for subtle, elegant branding.

-

Often used on packaging, leather, diaries, and business cards.

-

SPOT UV

-

Spot UV is a high-gloss, clear coating applied only on selected areas of a printed design.

Key Points

-

Makes specific parts shine (logos, images, headings).

-

Adds contrast between matte and glossy surfaces.

-

Creates a premium, eye-catching effect.

-

Cured instantly with UV light.

-

Tray and Sleeve Box

Why Choose Us

1. Premium Quality Materials

We use high-density, durable materials to ensure your packaging not only looks luxurious but also protects your products perfectly.

2. Fully Customizable

From size and style to finishes and design, we tailor every box to meet your brand’s exact requirements.

3. Free Services & Cost Savings

Enjoy free die & plate charges, free designing, and free customizable styles—all designed to save you time and money.

4. Quick Turnaround Time

Our streamlined production ensures your orders are completed fast without compromising quality, so you stay on schedule.

5. Free Shipping

We deliver your orders safely and efficiently, with no extra shipping costs for qualifying orders.

6. Expert Support

Our experienced team guides you through the entire process, from concept to delivery, making custom packaging simple and stress-free.